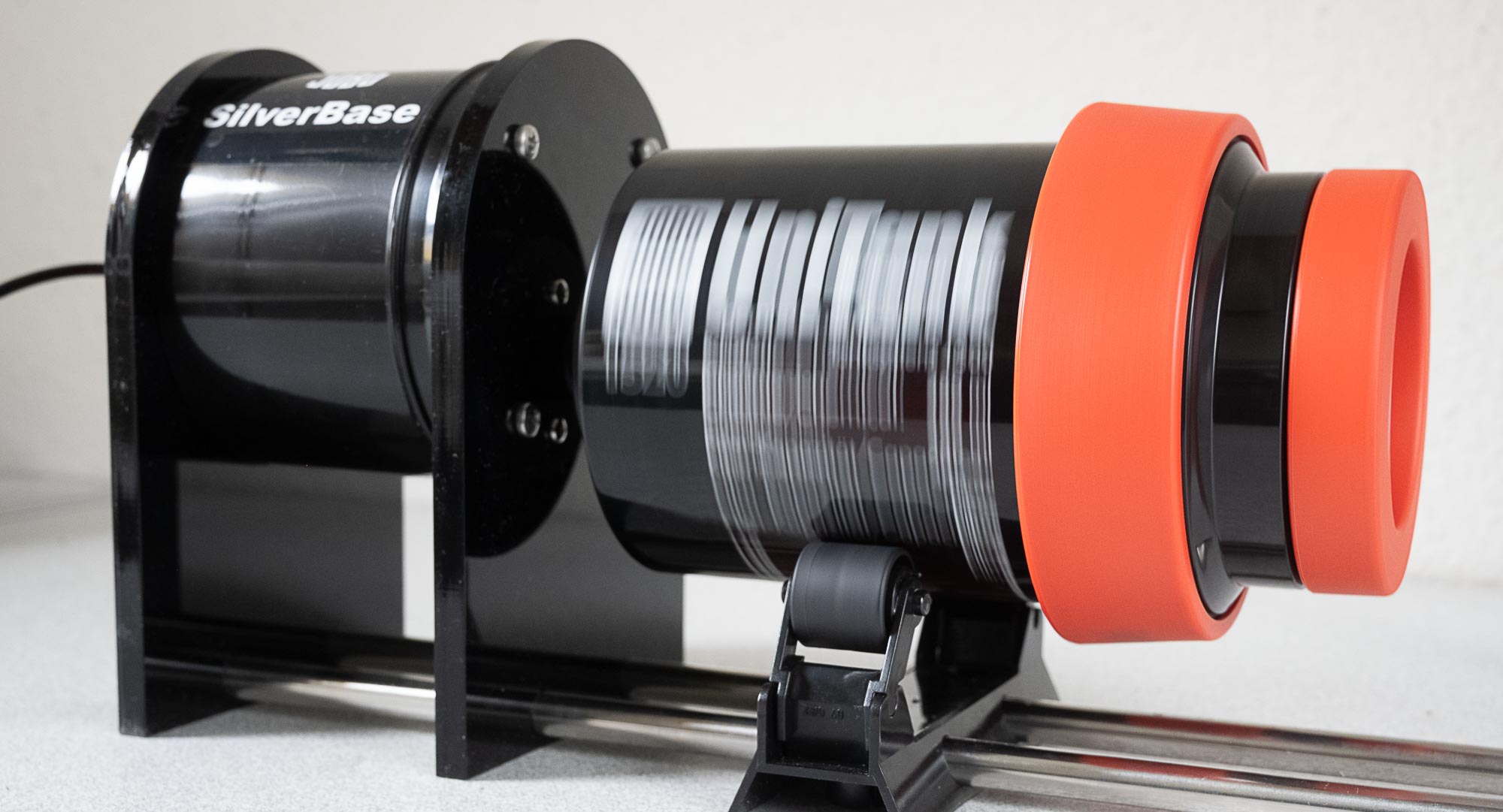

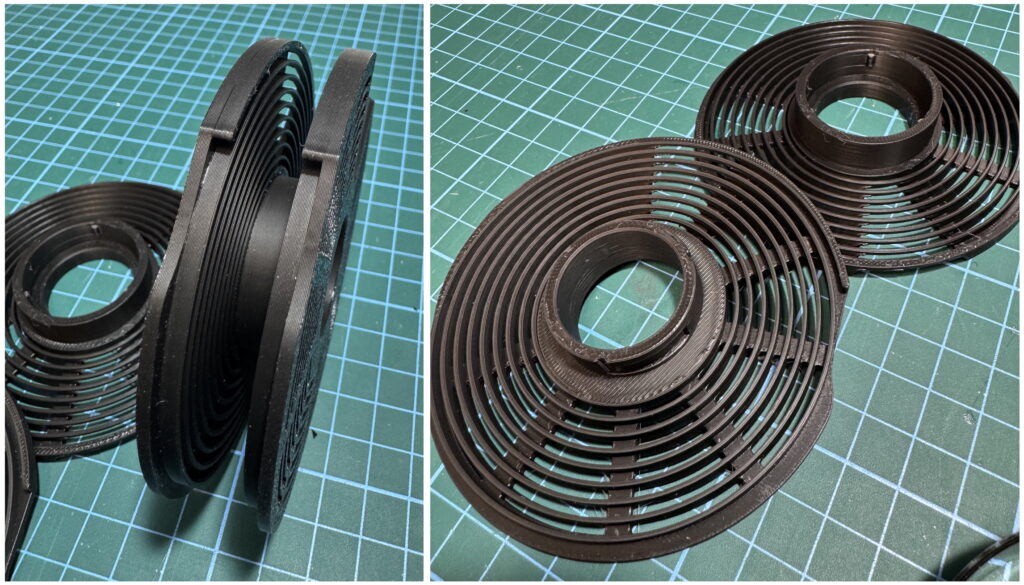

As far as film processing is concerned, recently switching to JOBO’s SilverBase rotary processor means I have come full circle on my pilgrimage on the path of film developing. I started off ages ago with rotary developing in two AGFA Rondinax tanks (one for 35mm and one for 120 film) dating back to the 1960s. Too many hiccups getting the film spooled correctly onto the spirals drove me insane and I consequently upgraded to JOBO’s tank system – basically when I could afford to do so. Fast forward to the present: after a short phase of experimenting with a very basic hand-operated rotary setup for said tanks I finally took the step to enter the luxury zone of accessible and reliable rotary development, which is what SilverBase is all about.

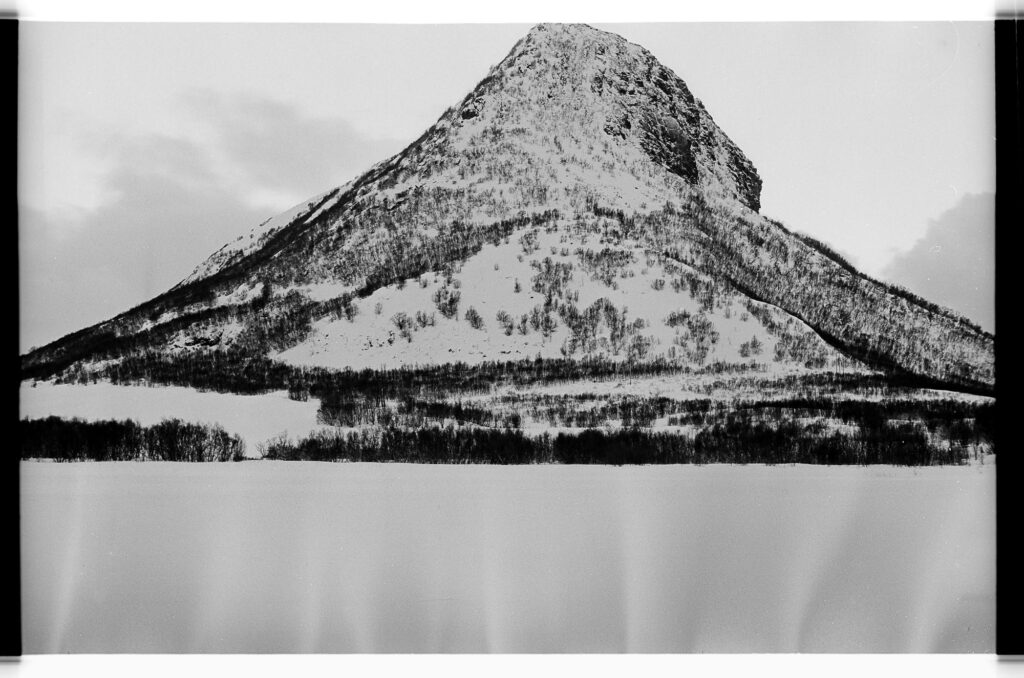

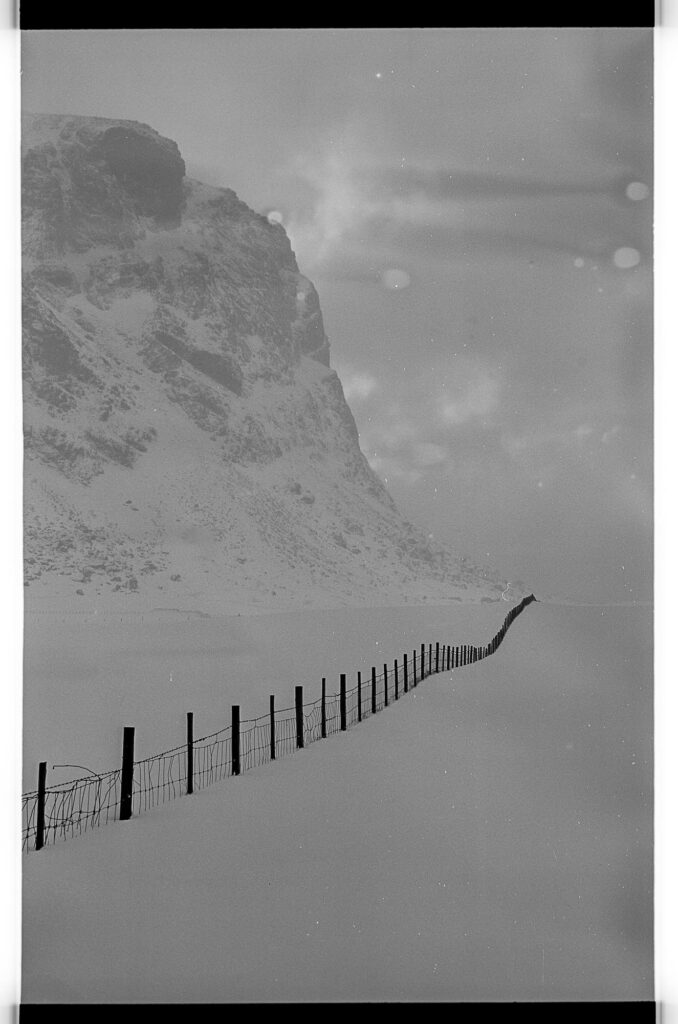

Shake it or stir it? Well, shaking – or rather inverting – the tank on a regular basis during development seemed to work okay to me for quite some time – as it has for tens of thousands of users for decades. Results were what I expected them to be. I took occasional glitches in my stride, but as time went by I found those pesky blotches and bromide run-offs on my negatives that I occasionally got more and more irritating, particularly on medium format and large format negatives. Advice from helpful photographers seemed to point in only one direction: try stirring – i.e. rotary development – for a change.

To cut a long story short, when JOBO announced SilverBase in September 2023 I took a deep breath and bought one of their first machines on the market. In the two years that I have used it since I have never looked back on this decision. Gone are the days of bromide runoffs and other irregularities. Each batch of films turns out evenly developed. Results are absolutely consistent and therefore dependable.

And about the luxury part: yes, I have become a bit lazy in the course of time. Inverting those tanks while strictly observing the guidelines regarding exact timing of intervals was always a bit of a hassle. Now it is just a case of flicking on a switch and letting SilverBase do the rest while I can already get the stop-bath or fixer ready or head off to the kitchen and make myself a cup of coffee.

What SilverBase is:

– a simple and very reliable and adaptable device for rotating JOBO tanks

– it will do the job in conjunction with the complete 1500 tank range (for 35mm and 120 Films) as well as the 2520 tank, mainly for 4×5 sheet film

– it will reduce the amount of developer used by about 50% on average, cutting down on cost per film

-tanks are very quickly coupled to the motor by a strong magnet

– compared to other rotary processors, notably JOBO’s own CPE-3 units, SilverBase is remarkably compact and affordable. I store mine on a shelf under the countertop of the lab.

What SilverBase is not:

– it is meant to be used for developing B&W films at room temperatures, as there is no water bath to maintain exact temperatures for C-41 and other colour processes

– there is no timer: bring your own smartphone or other timing device. JOBO might want to add this feature in the future

As far as developing times are concerned, there seem to be two approaches to this topic. You either give your film a pre-wash for about 3 minutes and cut regular development times by 15% OR you just forget about a pre-wash and carry on with developing times as per the spec sheet or your preferred bespoke recipe. I have adopted the latter method – it seems to tick all my boxes.

Kudos to JOBO for bringing this useful product to market.

Share this post:

Comments

Adrian Cullen on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 04/10/2025

The Silverbase is a great gadget. In addition to the standard procedure I use it to provide consistent agitation for the first 60 secs of stand development. I use DD-X and find that I could only achieve decent shadow detail by using DDX 1+9 for 1 minute rotation followed by 44mins stand when processing Delta 3200 (EI3200) .

Comment posted: 04/10/2025

M I Droz on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 04/10/2025

M I Droz on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 04/10/2025

Comment posted: 04/10/2025

Louis A. Sousa on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 04/10/2025

Peter Schu on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 05/10/2025

Comment posted: 05/10/2025

Nathan on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 05/10/2025

CHRISTOF RAMPITSCH on JOBO SilverBase – A brief look at the compact rotary processor – Shake it or stir it?

Comment posted: 06/10/2025