Universal Camera Corporation launched their Univex Mercury CC model in 1938, along with their proprietary #200 series films. It’s basically 35mm film, but on an open roll. The manual shows it having paper backing on the ends only, a bit like 220 film, to protect it from light while loading. Trouble is, the backing paper is perforated, which rather defeats the object.

The camera is often described as ‘half frame’ but that’s not strictly true. The image size is 25x19mm in portrait format, so it will just touch the perforations on both sides of 35mm film. Each frame winds the film on by 4.5 perforations, more than half of the 8 perforations for a full 35mm frame. The frame counter goes up to 36.

Can I use my camera?

I restored my Mercury a couple of years ago and finished it with some nice dark green leatherette. Since then I’ve been itching to use it. 35mm film will physically fit, if you can find a way to get it into and out of the camera without exposing it. The theory sounds simple. Inside a changing bag, just attach a length of 35mm film to both of the spools, roll it up onto the feed spool, and put it into the camera. I practiced on some old exposed film and found that there’s an awful lot that can go wrong. I could feel an engineering project coming on.

First, make a new spool

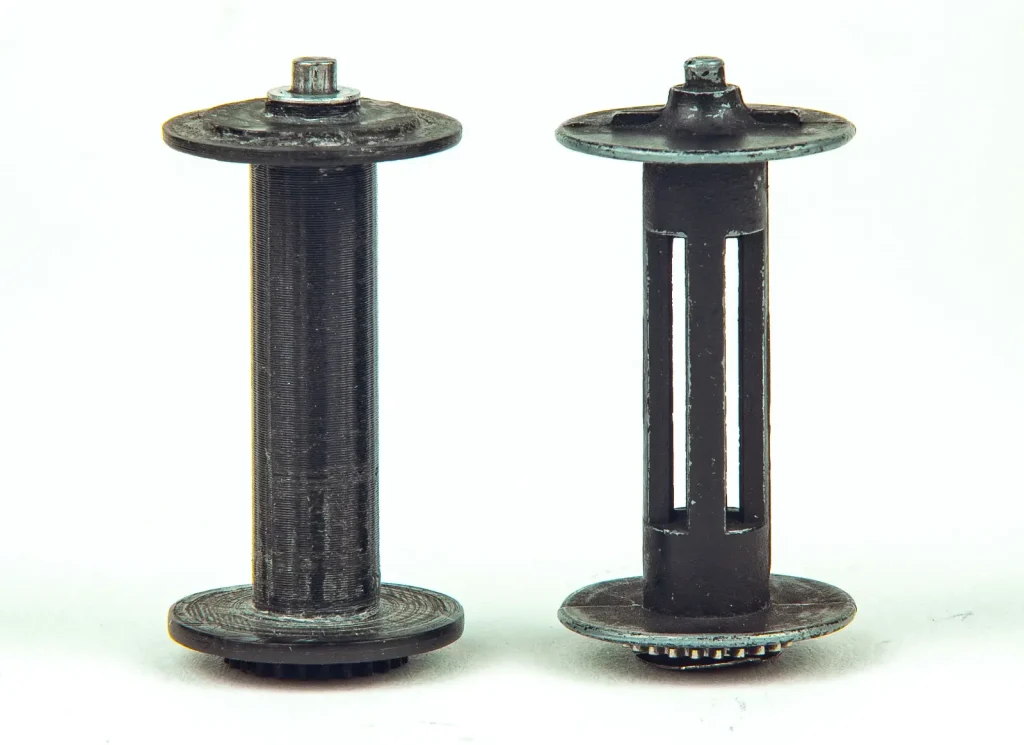

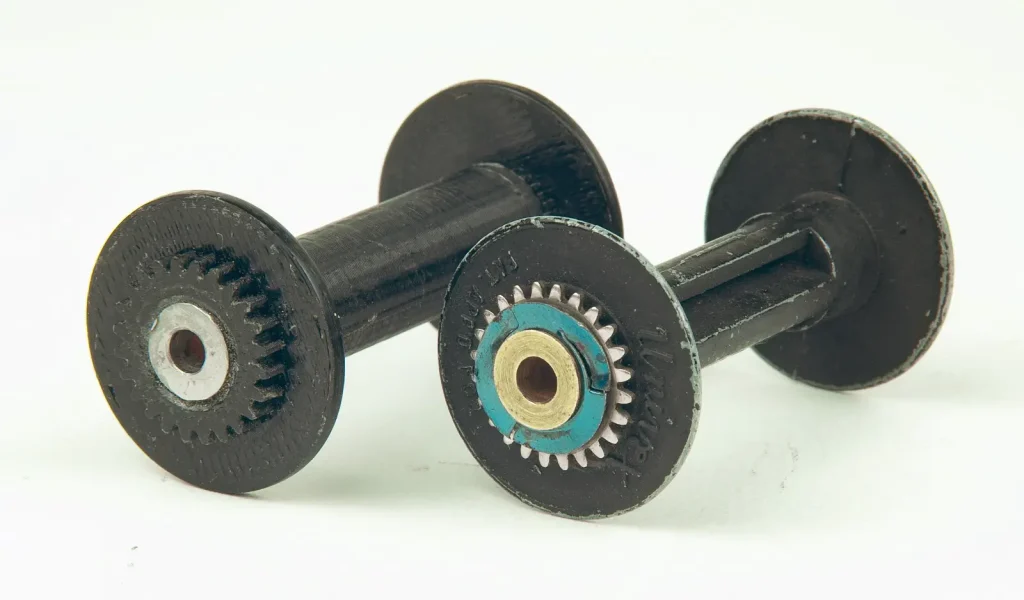

You need to have at least one original spool, because it has a special drive gear on the bottom. The gear isn’t fixed, but uses a spring washer that acts as a clutch and allows it to slip a little. That way the takeup spool can be driven a little faster than the film is coming off the sprocket, which keeps it tightly wound. On the feed side, the spool engages with a little gear in the film chamber that drives a film transport indicator on the bottom plate. My camera only came with one spool, but as there’s no need for a slipping clutch on the feed side I was able to 3D print another one with a fixed gear on the bottom.

Spool loading machine

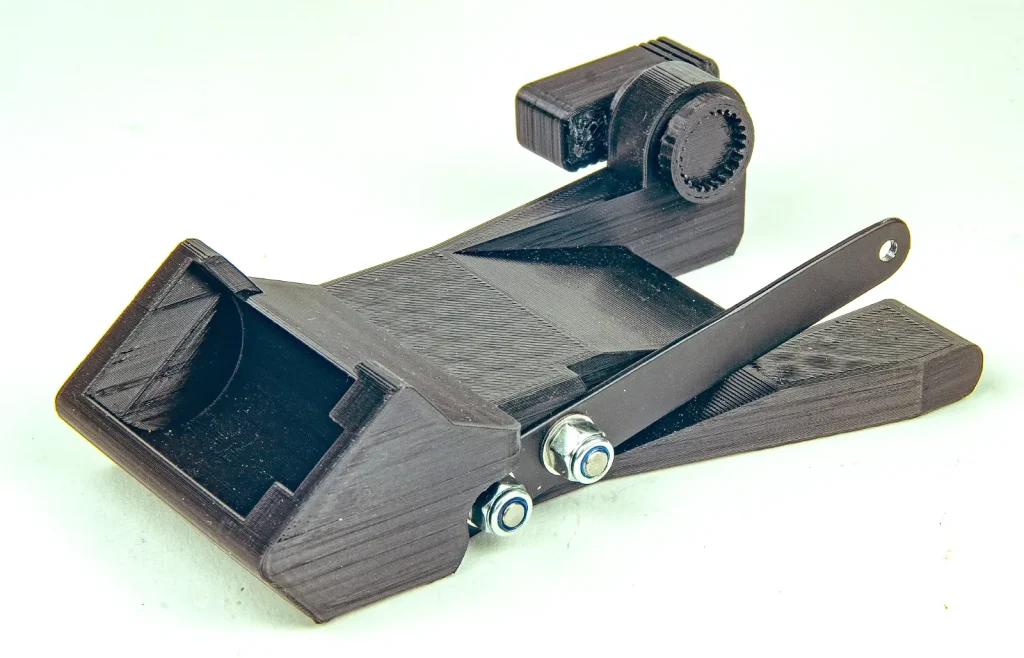

I used FreeCAD software to design a shape that would hold a 35mm cassette at one end, hold the Univex feed spool at the other, and enable the spool to be turned by a known number of revolutions. A steel arm is just springy enough to hold the spool against the drive knob.

This enables a good alignment from the cassette to the spool, so the film will go on straight. Once inside the changing bag, I pulled some film out of the cassette, cut it straight across, and used tape to attach it to the 3D-printed spool (which has no slots). Pinching the perforations on one edge of the film as it moves will maintain the tension and make sure the roll is tight.

Previous experimentation in daylight with an exposed film showed that half of a 135-36 roll is 17 turns of the winding knob. Once wound, I kept the film in place on the spool using a clip made out of 15mm plastic plumbing pipe. That meant I could cut the film without it all unravelling. It turned out to be enough for 27 exposures.

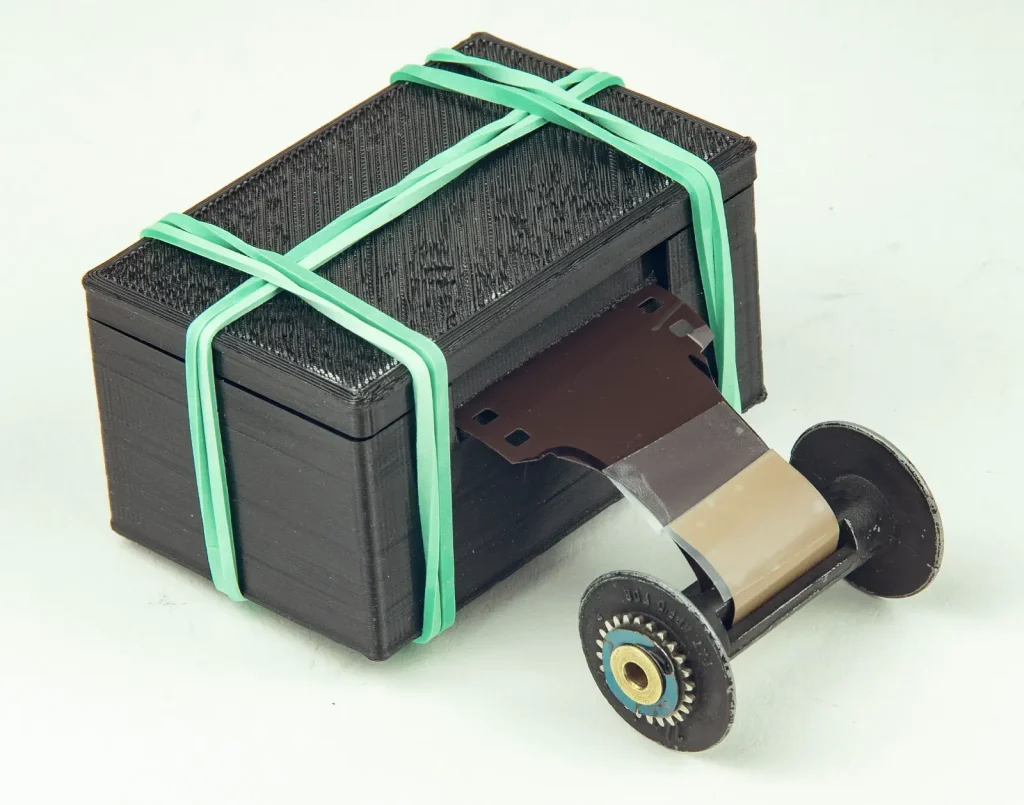

Now I need some daylight

I knew that attaching the cut end to the original spool inside a changing bag was going to be difficult. It has to be cut on each side to leave a central tongue 22mm wide. The tongue then needs to be threaded onto the spool, and a bit of tape to finish wouldn’t hurt. Tricky to do accurately. My solution was to find a way of doing that bit outside the changing bag. I 3D-printed a box with a sealed lid to put the loaded spool into. Then then it can be brought out into the light.

Now I could cut the film to shape and attach it to the spool without any stress, because I could see what I was doing. The only difficult bit is to remember to attach it the right way round.

Back into the changing bag

The box and the camera go into the changing bag. The box can be opened and the takeup spool put into the camera. The clip is removed from the feed spool and it is carefully placed into the feed side while keeping the film taut across the film plane.

Once the feed spool is in place, it needs just enough friction to stop it unravelling. Originally there was a thin sprung steel arm for that purpose, but it’s not a good solution. I added some thick open foam to provide just the right amount of drag.

Using the camera

For its first outing in decades, I treated it to half a roll of Extar 100 and took a trip to the seaside at Cromer, then finished off the roll on an evening photowalk in Norwich. It’s a delight to use, and the mellow ‘schhhhhhhhhhhluk’ sound of the shutter is totally unique. The only downside of that is shutter lag, between the start of the shutter disc’s motion and the image being captured. Despite the top shutter speed of 1/1000s, it’s a factor to remember if you want to try panning action shots. The tiny viewfinder discourages that sort of use anyway.

Take note of the spinning film transport indicator on the base when you’re winding on. As you’re getting towards the end of the film, start watching it like a hawk. When it stops spinning, you’re done and any more shots will just be multiple exposures.

The shots

What next?

The Mercury has interchangeable lenses, but no other focal lengths were available. The early Tricor 35mm f3.5 was superseded by an f2.7 version and a Hexar 35mm f2.0. The focus helicoid is behind the mount (which has an imperial 15/16″-32 UNF thread) so the lens itself doesn’t need a focusing mechanism. I might try to find a decent half-frame 28mm that I can adapt to fit. An accessory shoe for a bigger auxiliary viewfinder is conveniently placed above the standard one.

Share this post:

Comments

Paul Brant on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Great interesting post with some good shots .

Many thanks.

Comment posted: 15/07/2021

Tom Perry on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Comment posted: 15/07/2021

David Campbell on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Calum Davey on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Kurt Ingham on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Is there a possibility I could purchase copies of the spool and loading device from you? I have no 3D printing capability myself

Thank you

Kurt Ingham

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Comment posted: 15/07/2021

CP93 on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Philip Lambert on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

There are often cheap half frame cameras on eBay .

I bought an Olympus EES for £30 that works perfectly and another for£12 that seems to (untried). I have an old Minox 35mm somewhere that stopped working, optically very good. Back focus dimension unknown.

My Olympus gives sharp results on low-speed colour negative rated at half box speed. Maybe you could find a non-working example.

Phil

Comment posted: 15/07/2021

Eric Risse on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 15/07/2021

Comment posted: 15/07/2021

Louis A. Sousa on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 16/07/2021

Comment posted: 16/07/2021

Scott Gitlin on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 16/07/2021

Comment posted: 16/07/2021

Brian Nicholls on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 16/07/2021

Comment posted: 16/07/2021

Christopher Smith on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 20/01/2022

Stuart Jenkins on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 21/01/2022

Anyone who wants my STL files to 3D print can have them for free. It's far too niche to be able to sell them. I can put them on my Thingiverse account (stu_jenkins). Sounds like you're lucky enough to have two original spools.

Heiko Hahn on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 28/02/2023

Heiko Hahn on How I Loaded and Shot a Univex Mercury with 35mm Kodak Ektar 100 – by Stuart Jenkins

Comment posted: 28/02/2023