If you’re like me and you love shooting film (or at least you love film cameras), you probably know this feeling: you find an old film camera while strolling through your local yard sale, flea market, or simply eBay, buy it on impulse with some justification you’ve made up for yourself, and bring it home. The initial excitement is often followed by some kind of disappointment. You open the back to load film, only to find gooey old foam particles falling out. The shutter is sticky, the leatherette is peeling—things you didn’t see in the initial images—and after consulting Butkus for advice, you find out that your new acquisition needs a battery that’s been discontinued for years.

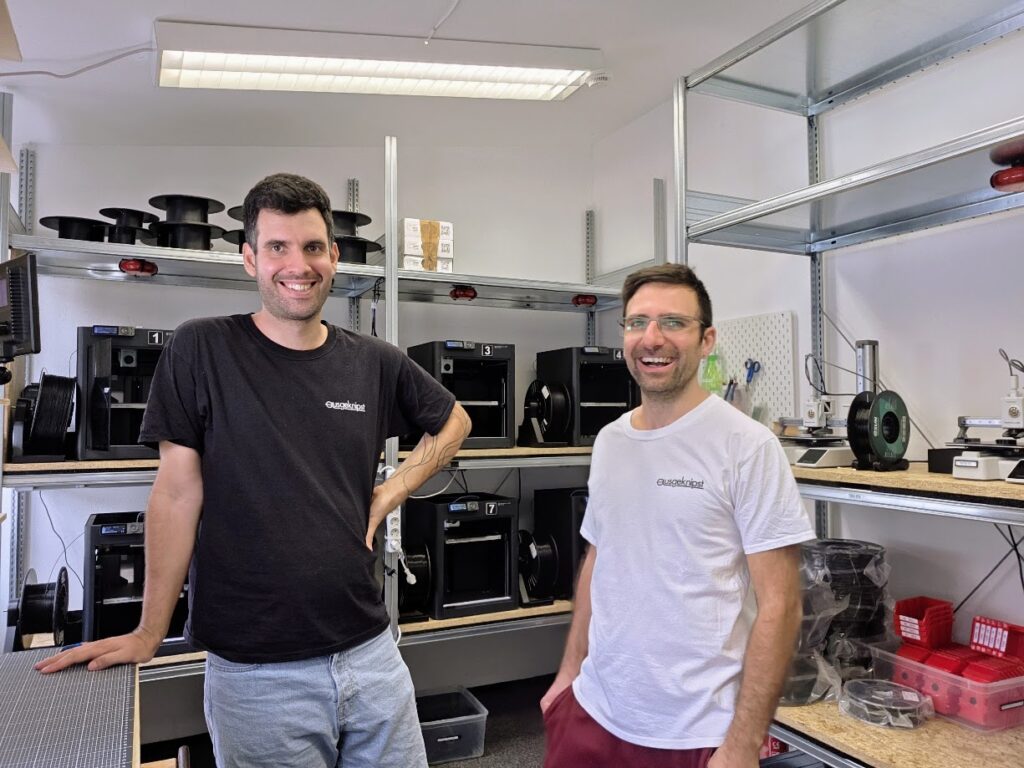

This exact situation is why my friend Antonio and I started “Ausgeknipst.” It wasn’t a big business plan; it was a problem that turned into a business: making the small parts needed to keep these old cameras working.

It All Started with a Flea Market Find

Our story isn’t that unusual for the analog world; it started with one camera. Antonio and I have been friends for years, and he’s the one who got me into film photography. He’d found an old Minolta 7xi at a flea market and he made me so excited about his camera that I bought a Minolta 7000i for myself shortly after. Little did I know that those old Minolta A-mount SLRs were a very good entry into the film photo world, as they are affordable, reliable and easy to use.

The hobby grew from there. We started teaching darkroom courses at a local youth center here in Würzburg, Germany. At the time, Antonio was an engineer and wasn’t happy with his job, while I was funding my philosophy studies by fixing and selling used cameras. The turning point was when I bought a couple of Canon EOS Elan 50, all with broken film doors and couldn’t find replacement parts to fix them.

We realized that instead of refurbishing entire cameras, which is very time-consuming, we could focus on these smaller, common problems. The need was clearly there because we were facing it ourselves. Antonio filmed me while I was replacing the broken battery door latch, we uploaded this rudimentary how to instruction on Youtube, started selling this and similar replacement parts on eBay and people started buying it.

From Request to Reality: Our Process

Today, we have over 500 products in our store. The ideas come from two places: our own camera bags, and, more importantly, from the community. We ask for suggestions, and at least half of our products started as a customer request.

So what happens when a request comes in? Take a part we’re currently developing: a battery solution for the Rolleiflex 6006. The process is usually the same. A customer, often someone who bought something from us before, will ask if we can help with another camera. I’ll then check the market for alternatives and see if there’s enough demand. For the Rolleiflex 6006, the existing solutions are either expensive or require soldering. Our approach is that our customers are photographers, not tinkerers. We aim to provide a solution that works so people can get back to shooting.

Once we decide to go for it, we buy the camera. Then our CTO and chief designer, Antonio, starts designing prototypes. As most of our parts are 3d-printed and printing takes time Antonio and our second designer, Lars, simultaneously work on different project at once, which means that their tables can get quit crowded at times.

When design work is finished, we source components, maybe order custom PCBs, contacts, screws and cables. Then we’ll produce a small batch and send one to the original customer for testing. Their feedback is essential. It rarely works perfectly the first time; many of our parts are on version 7 or even version 17. That’s just the nature of our production process; we can constantly improve designs based on how they’re actually used.

The Engineering Challenge: Materials and Difficult Projects

The devil – however – is in the details. For most parts, we use PLA+, as it’s a good all-rounder. But for more demanding parts, we have to get more specific. Some of our battery clips are now made from PETG-CF, a carbon-fiber reinforced material that prevents “material creep” under constant spring pressure—a lesson we learned from experience.

And we’ve definitely had some challenging projects. The one that comes to mind is the battery clip for the Minolta XM Motor Drive. The XM is a rare camera, and the original battery clips were designed so poorly that they all break. Marwan, the editor of Silvergrain Classics, visited our office and asked if we could redesign them. Looking at the part, we thought it would take a week or two.

It turned out to be much more complicated. The first versions broke, which was quite frustrating, as this is what made it into the article of the current issue. We couldn’t source small enough springs, and larger ones put too much stress on the housing. The original PLA material started to deform over time. I think we are now on the 20th iteration of that clip. The latest PETG-CF version seems to be holding up, but it was a long process.

A Case of Gear Fatigue? What I’m Shooting With

You might think being surrounded by cameras all day would make me a huge gear nerd, but it’s had the opposite effect. I used to dream of owning a Contax G2 or an X-Pan and I had a Leica M3 for a while. But working with all this gear led to a kind of gear fatigue.

I switched the Leica for a Minox 35 GT because it was compact and I wasn’t afraid to take it everywhere. After some reliability issues with those, I moved to the Pentax 17. And honestly, for the last year, I’ve been using my smartphone a lot. The smartphone cameras are great, and it helps me focus on the photography more than the gear. When I want something special I will still grab my trustworthy Leica M8 (which has a broken display, which makes it half a film camera in my opinion).

A Pro Tip From the Repair Bench

Seeing so many cameras with the same recurring problems gives you a certain perspective. If I could offer one tip to someone buying a used camera, it would be this: consider getting something on the cheaper side. In my experience, if you own an expensive camera, you often hesitate to take it to certain places because you’re afraid it will get damaged or stolen.

For robust and affordable choices, Minolta’s SRT line (like the 101 or 303) or the Canon FTb are good options. They’re mechanically very reliable and built to last, though they are quite heavy.

Personally, I’m still a fan of the Minox 35. They can be hit-or-miss, with a sticky shutter being the main problem, but a working one has superb image quality for its size. If you want something new, the Pentax 17 is enjoyable. It’s light, the half-frame format is fun, and getting more shots from a roll is a plus, considering development costs.

In the end, the best camera is the one you actually use, and our goal is to help make sure these old ones are still usable.

Whats next?

We moved to a bigger office space this year and are constantly improving our bestsellers, designing and releasing new products and learning new skills. Currently we are working on some film slitters for use of standard 35mm or 120 film with those miniature and sub-miniature format cameras like 110 (16mm) and Minox (9,2mm). Other then that we are expanding into the cine branch of film with some modern day battery solutions for the Beaulieu 4008, R16 and 2008, as well as the Bolex H16 EL and lastly we also built our own (affordable) copy stand, which should be available any time soon. If you want to stay up to date with current releases you can follow us in Instagram, Youtube our Subscribe to our newsletter at ausgeknipst.de.

It’s been a bumpy ride but I enjoyed (almost) every bit of it and I am hopeful that film photography finally found it’s place alongside digital and smartphone photography. At last I want to thank all those followers, supporters, tinkerers, bloggers, niche-format enthusiasts, Analoge gearheads, our friends and our families for the ongoing support and love!

Lastly I want to encourage everyone who is reading this and has some kind of problem with his or her camera that we might solve to reach out to us through our socials! Most of our product ideas come from enthusiasts like you and we will send everyone a free sample of a new product who gave us a good hint for a new product.

Share this post:

Comments

Zheng Li on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 23/08/2025

Comment posted: 23/08/2025

Gary Paudler on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 23/08/2025

You have my admiration for finding a niche that you enjoy and turning it into a thriving enterprise.

Comment posted: 23/08/2025

Gary Smith on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 23/08/2025

Thanks for your article, you may pick up some business from it.

Comment posted: 23/08/2025

Alastair Bell on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 23/08/2025

Keep doing the great work you're already doing.

Jeffery Luhn on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 24/08/2025

Jeffery

Comment posted: 24/08/2025

Uli Buechsenschuetz on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 24/08/2025

I'm glad I've found you on eBay some time ago. Saved me some trouble finding other batteries adapters and accessories. Just this morning, after reading your article, I went out with my Minolta and two lenses, just to notice that on the additional lens I had one of your lens caps...

I also want to mention here that you were really helpful when I bought a camera from you which bricked shortly after and you took it back without problems.

Keep up the good work!

Comment posted: 24/08/2025

Jeff Greenstein on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 24/08/2025

Comment posted: 24/08/2025

Russ Rosener on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 24/08/2025

It is very satisfying to bring an old camera back to life. And it keeps the landfills empty!

Keep on going!

Comment posted: 24/08/2025

Leon Winnert on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 25/08/2025

Nick Orloff on Breathing New Life into Old Cameras – The Ausgeknipst Story

Comment posted: 15/02/2026