I’ve just started shipping pixl-latr – a product I launched on Kickstarter in June 2018 with an expected delivery date of September the same year. In short, I’m 22 months behind schedule. Despite that, I still have the confidence of a lot of my backers, and though it’s been extremely stressful, I’ve actually really enjoyed the process – for the most part at least…

It’s now the weekend of the week that I started shipping and, as far as I know, very few people received theirs yet. This is giving me an odd combined sense of both relief and trepidation. Relief at the fact that I’ve finally started shipping, and trepidation about how well pixl-latr is going to be received.

There’s a lot in the balance here, not least the fact that I’ve just employed Josh to help me run the company. What will be, will be, I suppose. But, before I’m ready to move forward, I thought I would take a moment to reflect on the last couple of years. Writing often helps me solidify my thoughts, so maybe writing this article is a bit of a process of catharsis or therapy or something. Or maybe it’s just a combination of the fact that all this is the only thing I’m capable of thinking about this weekend and that I’ve been so hectic dealing with it all this last week that I haven’t had a chance to write anything else… either way, here’s a bit of a brain dump for you:

The Stress

In the 22 months this project has run behind schedule – in fact the 25 months since it went live on Kickstarter – I’ve also continued to run this website, helped keep my creative agency afloat, started (and stopped) selling lenses I was buying in from China, opened a coworking space in Worcester where I live, moved house, had pretty much all of this threatened by Coronavirus, quit coffee and even massively reduced my alcohol intake. But if you asked me what out of all of those things has given me the most sleepless nights, what has caused the most stress and what has taught me the most both about myself and the processes I’ve undertaken, I’d give you one slightly-annoyingly-spelled hyphenated word: pixl-latr

The Abridged Version

If you don’t know anything about pixl-latr, it’s a product I dreamed up and then spent about 5 years thinking about and trying to get designed. After working with a couple of design companies that couldn’t make sense of my ideas, I eventually met Steve Lloyd who helped me create a prototype that actually worked. At this point, I put it on Kickstarter where it raised 66,933. I then used that cash to have it redesigned again, then spent about 25 months trying to have the new design manufactured.

For all those years I’ve spent working on it, you might imagine it to be some sort of complex product. In actual fact, it’s a very simple product with a very simple purpose.

A Simple Product

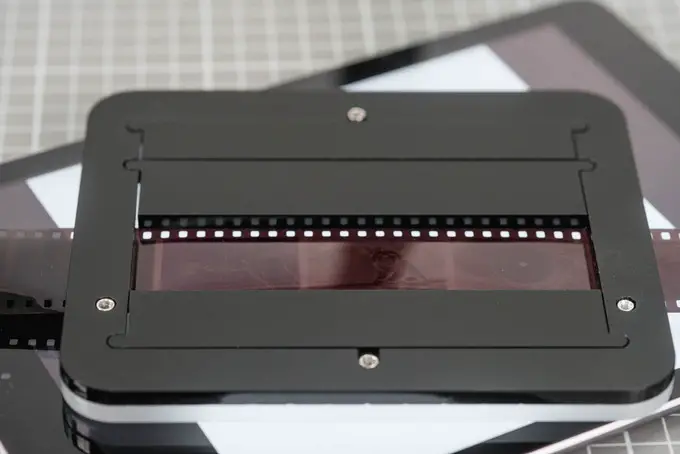

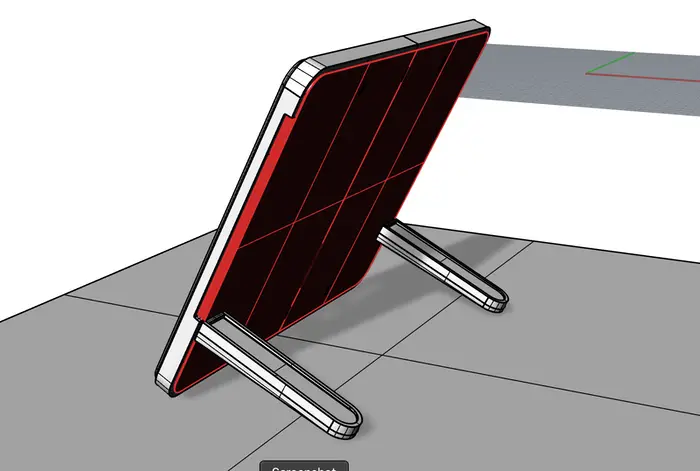

The function of pixl-latr is to aid in the process of digitising film with a digital camera. It does this by holding the film flat and diffusing and masking a backlight. It’s made up of 4 parts (or sets of parts): the frame, the gates which slot into the frame to mask different film frame sizes, a diffuser that slots into the frame and two legs to optionally stand it upright.

With a strip or sheet of film inside it, it is placed on or in front of a light source to illuminate the area of film to be digitised. A digital camera is then used to capture the image on the film. That digital image can then be processed on the computer for sharing online or printing etc.

Simple! So why has it taken so long?

The Long Version

As I’ve said, I decided that such a product needed to exist quite a few years ago now – around 7 years in total I think. I’d bought a large format pinhole camera and wanted to be able to easily digitise the negs with a compact digital camera I had. I found there was a hole in the market for such a product so proceeded down the road of trying to bring something to market. Of course, I had no idea what I was doing, and though I had met and had some really good advice from a few people in the first 4-5ish years (thanks Mel!), progress was very slow. The problem I had was finding someone to work with who would encourage me and work very closely with me to find a design that truly worked.

Steve Lloyd

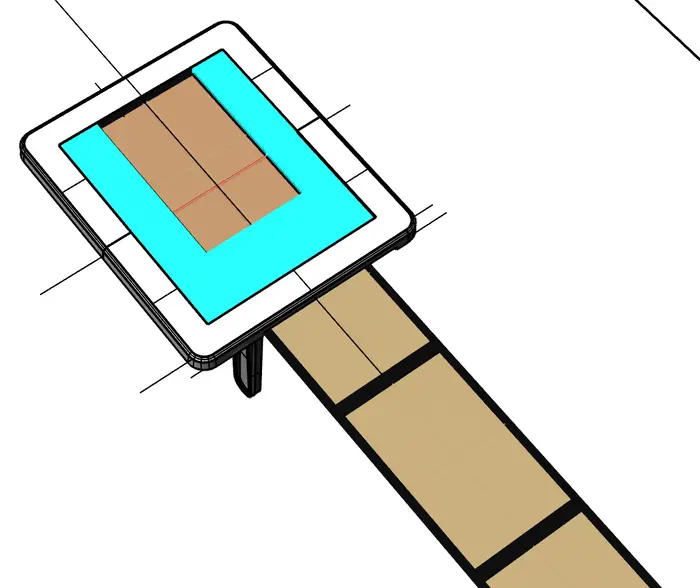

I then met Steve Lloyd who now owns and runs Chroma Camera. Steve really changed the game. Not only did he bring his own ideas and thoughts to the table from the perspective of a film photographer, but he also encouraged me to expand the concept beyond one that would just work for 5×4 negs. Between us we came up with this:

Kickstarter

Quite satisfied with this design, in June 2018 I took it to Kickstarter and somehow managed to raise that aforementioned slightly ludicrous £66,933. I honestly couldn’t believe it. I still can’t. I remember the first 3 hours of the Kickstarter watching the pledges surpass the original goal of £9840 and then carry on climbing at quite a rate. It was a surreal experience.

Then the Kickstarter finished, and I had all that money (minus fees) on the way. But as excited as I was, doubts began to creep in. This was a lot of money! I felt that I’d had a lot of people put a lot of trust in me to deliver something good. And whilst I was quite pleased with the laser cut design, it had a few issues that made it a little less than ideal.

Having a product cut out of sheet acrylic was great for cost and ease of manufacturing, but limiting in terms of how it could be designed. As such, the parts didn’t slot together perfectly or hold together with any friction, it had some shiny edges that sometimes caused issues, I also had some concerns about it sitting flat on a surface when it was lay down, and the general fit and finish – whilst good – just felt a little lacking when held up against the large sum of money I’d raised.

Ellis Pitt

All these slight doubts came to ahead when I sought advice from a chap I know called Ellis Pitt, a manufacturing and engineering consultant. He saw merit in the idea, but felt the product felt looked like a prototype.

I also felt that the money I had raised gave a really big clue to the appetite of the marketplace. Something like 1707 people had thought this was a good enough idea that they were willing to throw some cash at it. I felt that I had an opportunity here. If I could use this money to redesign pixl-latr and make it even more of a product than it was, I could really run with this as a business – and as someone who wants to see the film photography industry grow, this felt like a good thing!

The problem was, I couldn’t afford to deliver the laser cut product and redesign it from the ground up. So I decided to break the news to the backers that there would be a bit of a delay whilst I went back to the drawing board. Little did I know, that decision would be the start of a very frustrating 2 years.

Re-re-re-design

Of course hindsight is a wonderful thing, and actually, I still stand by the decision I made 100%. The product I have at the end of those 2 years is a big step up from where I was. And even with a whole load of other products that have come to market since, it’s still the only one at the price point that works with 35mm, 120 and 5×4. In fact, the closest thing is twice the price I think. So I’m still very pleased with what I’ve achieved… despite the time it’s taken!

So what, you might ask, has taken so long? Well, honestly, looking back, I’m still bewildered by it myself. Ultimately though, beyond a few cases of human error that I will get to, it comes down to two manufacturing issues: draft angles and tolerances. The latter of those words actually gives me a bit of a twitchy feeling even writing it down. But before I get to those, let me take you back a bit further to a bit that went more smoothly.

Clive Goodwin

Not long after I spoke to Ellis, I started talking a contact of his by the name of Clive Goodwin. Clive used to be the top dog in the design department at Samsung Europe, so is not short of product design experience. I’d really landed on my feet with Steve – working with someone who understood photography really upped the pace of the development of the product. To take it to another level though, I felt that going to someone who’d worked at the dizzying heights of industrial design Clive had couldn’t be a bad thing.

After a couple of calls and a 3 hour meeting with Clive at a restaurant in Weston-super-Mare, Clive was well versed enough in the problems of the design to come up with a solution that really felt like it would work.

These were the first teasers of the new design that I shared:

I can’t tell you how impressed I was at the speed he devised the solution. Here was a render I shared soon later

We soon had a prototype…

We soon had a prototype…

…that felt like it worked very well!

I just now had to have the thing made!

China vs. Paterson

The design Clive had come up with relied on injection moulding. Injection moulding is a great way to bring the unit cost down, but its disadvantage is that it also comes with some heavy front-loaded expense in the form of the tooling. For the tooling, I had two real choices, find someone in the UK or go to China where it would be cheaper. The former would give me more confidence at higher expense, the latter would be a lot cheaper.

After engaging in a local business support program that provided a small about of funding and some advice – despite having had some very interesting quotes from the Chinese – I decided to pursue the idea of manufacturing in the UK. I think there is something of a control freak in me that made me just want to be able to drive the wherever the tooling was being made to be able to prod at it and interrogate it with my own fingers and eyes. If there was to be any problems – which of course there were in the end – I wanted first hand input into the solutions. We’ll never know how the well it would have gone if I’d gone to China, but if it had gone as badly as it went in the UK, I think that would have been the end of the project.

Anyway, I digress. The organisation in the UK that gave me the funding also helped me find a manufacturer. I’ll never forget the moment when Kylash (the guy that was giving me the advice) suggested I should speak to a company he’d been working with for some years, “You might have heard of them” he said, “they already make photography products under the brands of Paterson and Benbo”. I had a Benbo tripod in the office, and, well, what self respecting film photographer hasn’t heard of Paterson?!

Paterson (Phil & Richard)

Of course, tooling and manufacturing in the UK was always going to be a lot more expensive. But – though it would be unprofessional of me to divulge the details of the deal – Phil and Richard from Paterson made it very clear how keen they were to work with me. We struck a deal, and just before Christmas 2018 the path to an injection moulded pixl-latr was set in stone. Of course, what I then didn’t know was that same path was also the path to about 14 months of tooling headaches.

The Tooling Disaster

I’m a strong believer in the idea that whatever project I’m leading the buck stops at me. So before I get any further into this, I want to make it 100% clear that I take ultimate responsibility for all of the issues that followed. Ultimately, everything that has happened has come down to choices I’ve made – choices I’ve had to live with the outcome of since…

The tooling was supposed to be made early 2019. Unfortunately, the guy Paterson outsourced the tooling to was running a bit behind schedule. As such there was some delay to the process of the tooling being made even beginning.

In hindsight, I feel like I wasted this bit of downtime. All I did was push and nag for the process to begin. What I should have done is pushed and nagged for a bit of time to be spent with the tooler – a chap named Jan – to make sure he understood the drawings.

I’d been reassured by Phil that he would understand them and that there wouldn’t be any issues with the design. Paterson and its parent company have been working with Jan for 20 years by this time, and though he was sometimes slow, he apparently had a 100% track record. Phil has zero concerns. But my gut feeling was that I wanted to make sure Jan knew what he was doing. I ignored that gut feeling, which would turn out to be a mistake.

The Tooling

The tooling for pixl-latr is in fact two tools. If you don’t know anything about injection moulding, the tools are made of large chunks of metal that sandwich together in a machine and have melted liquid plastic injected into them. The plastic then cools inside the mould, the metal tools are pulled apart, and the injection moulded part falls out the bottom of the machine. Sounds simple, but of course the tool has to be very precise – especially when you’re dealing with friction fit parts as I was going to be. There’s also a need for something called a draft angle. The draft angle is something required so the parts can be released from the tool.

These draft angles were also the cause of a large part of the issues with the tool. In short, seemingly because Jan didn’t fully understand the product, he decided to change the draft angles on the tool for the gates. The result of this was that whilst the gates didn’t fit into the frame the first time around – not unexpected really – the basic idea of them fitting with some level of friction was never going to work because the draft angles on the frame were opposed to the draft angles on the gates. The video above is me talking a bit about this at the time.

Make sense? No? For the sake of this story, it doesn’t matter. What does matter is that this issue would end up taking something like 14 months to fix and would take me right to the brink of my patience. The amount of times I visited Paterson’s factory to try latest versions of he gates to find, yet again, that they didn’t fit was just absurd.

As I’ve said, had the Chinese made this same mistake, I just don’t think we would have ever found a way to the solution – not for many more years of trying at least. Fortunately, I wasn’t dealing with someone on the other side of the world. Instead, I was dealing with a totally bewildered Phil and Richard at Paterson in Tipton, just 45 minutes drive from my house.

I say bewildered as specifically Phil’s disbeliefs how wrong things had gone even outstretched mine. Having worked with Jan for so long, and having never had any issues with his work – even including on some much more precise designs than pixl-latr – I don’t think he could quite believe how things escalated to the levels of ludicrous that they had.

But anyway, there little point in me recounting the story blow-by-blow. If your feeling masochistic, you can trapes your way back through the 70 odd kickstarter updates. Suffice to say, I lost a lot of sleep over that period of my life. In the end though, we got there. And all of a sudden I had 27,000 injection moulded parts sat in cardboard boxes taking up space in Paterson’s warehouse.

The Diffuser Debacle

The next issue was the diffuser. The funny thing about the diffuser is that I quite genuinely had no idea it could cause so many issues. The diffuser is just a bit of laser cut acrylic. To my mind, it just needed to be cut to shape – how hard could that be?! Well, for so many reasons – not least Covid-19 – this part of the project would slow to nothing too.

Karl

To begin with I was using Steve Lloyd’s mate, a chap called Karl. Karl’s been pretty good dealing with me over the last few years. He’s certainly had to be patient – I ordered a whole load of acrylic that he had to store for me for about 18 months. Once the frame design was finished, we were ready to start finalising the diffuser. Unfortunately, for a long while, I was never quite sure when the frame was finished. Because the gates and frame needed to fit perfectly together, even when the frame part was largely finished, I was worried that there would be more changes required. So I held off the diffuser part of the project for as long as I could.

Eventually, some time late least year, maybe even early this year, I started pushing Karl to get the final diffuser design sorted. To begin with, this was a bit of a back and forth process between Clive in Cornwall, me in Worcester and Karl in Liverpool. Clive would make a tweak to the file, send it to Karl, Karl would cut it and then post it to me. This process didn’t work – it was just too time consuming – so eventually I went up to Liverpool to meet up with Steve and Karl and between us we made a version of the diffuser that fit.

Brilliant! Well, it would have been if Karl’s laser cutter hadn’t then broken a few days later… No problem, I paid my invoice upfront, so he could buy another. Then the new one didn’t cut the acrylic the same shape, so we had to redesign it again slightly. Of course, now Karl knew the fit I wanted so he was able to do that bit himself. Great… until the new laser cutter caught fire. Fortunately, not much damage was done, so he soon managed to get it to cut 300 units for me which I went up to Liverpool to collect and then took to Paterson. Unfortunately, for some reason, those 300 didn’t fit – they were too tight in the diffuser which bent it and meant the gates didn’t fit. Another disaster!

Then a really, really big disaster happened in the form Covid-19. Of course, Karl had to shut down for a month or so and the project ground entirely to a halt. Then, when trying to re-open to restart Karl managed to cut his hand (quite badly) and had to have a few days off, which meant he got behind. Then he was taken ill with Vertigo and laid up for a few days again and so got even more behind – not just on my job – but on other work too. Not his fault, just a perfect storm of a situation that seemed to mean my diffusers would be delivered too slowly.

Graham to the Rescue

At which point, the whole project was nearing the two year anniversary since I launched it on Kickstarter and I just couldn’t wait any more. In a moment of frustration that felt like I was going to burst, I decided to cut my losses and I rang a laser cutting company in Worcester about 10 minutes drive from my house. A chap called Graham answered, and after ranting at him for about 10 minutes about my woes, he just said, “don’t worry, bring the parts here, I will sort it for you!” I drove straight up to him that afternoon. 3 weeks later, after a few minor hiccups, we had a diffuser that fit, a repeatable process for making them, and as of Friday about 1000 diffusers cut with 2000 more on the way next week…

Shipping

… which, of course – at least once we had finalised our shipping processes – meant we were able to start shipping direct from Paterson’s warehouse last Thursday!

The Bits I Skipped

Of course, as you can probably imagine, I’ve skipped over quite a lot of stuff here. As it turns out, bringing a product to market involves a whole heap of other things to think about. And with such an unexpectedly protracted process, there have been a whole load of other ups and downs to contend with too.

For a start, there was bit where I started taking pre-orders on my website telling people it would only be a few months until delivery – that wasn’t long after the Kickstarter ended… Then there was going to the photography show in March 2019 and selling pixl-latrs to people there telling them they would only need to wait about 5-6 weeks…

Here’s me jabbering on at TPS 2019 about it

Then there was the more boring stuff like finding out if we did or didn’t need a CE mark (we don’t). The bit where I sunk a stack of cash having the design protected. Then there are the things like packaging and the shipping considerations that comes with it. Not to mention the branding, the design of the packaging, the website, instruction book, the pin badges that I offered as part of the Kickstarter (and then completely forgot about for ages) and the product photography… and probably a load of other stuff I’ve forgotten…

Fortunately, thanks in part to the fact that I run a creative agency in another life, and the fact that I had so much time whilst the injection moulding bit went so catastrophically wrong, I had plenty of time to get my head around this stuff as well as some of the required experience. But that doesn’t mean that any single part of it didn’t come with a whole load of stresses and strains…

…not least the fact that whilst all this was going on, I still had to manage the expectations of the Kickstarter backers!

Richard Slade

Just for a quick moment I’m going to take this story all the way back to before I launched the campaign when I met up with a guy called Richard Slade. Richard runs a company a little bit like my creative agency, but his focus is entirely on running crowd fund campaigns. He gave me loads of great advice about pre-campaign PR that really helped, but one thing he also recommended was that once the campaign ended, assuming it was successful, I should manage the expectations of backers as well as I possibly could.

This didn’t come as a surprise to me. I’m sure anyone reading this can think of a couple of Kickstarters that have gone awry through poor communication…?! But hearing it, being told it without any uncertainty from a professional in the field really helped.

The funny thing is, now, 25 months on, I would say the project would have failed if I hadn’t communicated as openly as I possibly could. There are things I didn’t share, for sure – stuff that wouldn’t have been professional to share, or could have caused damage to the project. But everything I could share I did share.

The backers

There were two really good things that came from this. The first was the absolutely fantastic support I had from the backers. There were so many moments when I was nervous beyond reason about posting an update. Fearful in fact that the backers would reprimand me for my course of action. But almost every time I shared news, I was given moral support and egged on. This moral support was absolutely vital in the continuation of the project.

The other wonderful thing that came from the Kickstarter backers was the advice and accountability. My backers almost became a bit of an advisory board. Even the people who made digs at me were helpful – there was a couple of snide comments that either kicked me in the butt, or changed how I did things slightly. Of course, there were a couple of folks who made comments that just had no bearing whatsoever on the project, but they were largely ignored – or occasionally commented at in my most polite (passive aggressive) way… but even that helped in a way, as it allowed me to let off a bit of steam.

The point is, the Kickstarter backers were – like everyone else I’ve mentioned in this article – a great help in seeing this project through. So – and without wanting to get too mushy – thanks everyone! It really has been emotional!

So where now?

Well, I’m finishing writing this on Sunday night. We posted 150 pixl-latrs last week, and hope to ship the other 1850 in the next 10 working days.

So far, I’ve heard from 3 people who have received a pixl-latr, and all of them are happy with what they have received. But that’s 3 out of ~2000. I’m not counting any chickens just yet. That said, I am looking forward with a more-than-averagely positive attitude. I’ve sold 50 more pixl-latrs over the weekend, which has helped my mood too…

I also have what I think is a strong plan moving forward. I’ve just employed Josh who’s been working with me 3 weeks and has so far already proved himself entirely indispensable.

We have a fairly well rounded marketing strategy, a loan in the bank, and a plan for phase 2 which has a working title of ‘pixl-lit’ or ‘pixl-luminatr’ (probably the latter since it’s harder to type/spell). This is, as you might guess, a light source for pixl-latr.

I also have lots of other little plans such as our “open gate platform” which is going to allow for makers in the community to submit 3D printed gates for other film types to pixl-latr users via our website. we already have a 3D printed mounted slide holder ready to launch on the platform, and a bunch of other ideas for weird and wonderful gate types too. I’ve also got a phase 3 on the far horizon – but more on that another time…

So yeah, all in all, things are looking good, and I’m feeling pretty positive. I was right too – writing all this down has been therapeutic! Thanks again to everyone who has supported me, goaded me, given me grief, and in every way shape and form engaged with the project over the last two years – it’s really been appreciated!

If for some reason you’re interested to read more about how the last 25 months have gone for me, you can read all of the kickstarter updates here – it’s funny reading the early ones… I sound so naive – so many lessons, learned…!

And, if you like the look of pixl-latr, you can order one here

Share this post:

Comments

Stala on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

Looks like I can order one myself ????

rick on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

Dale Willetts on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

Comment posted: 27/07/2020

Omer on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

Congratulations.

Terry B on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

And I'm sure that despite everything, you've a better appreciation of what going from a concept to an actual finished product entails. In a photographic sense, just think of all those prototypes made before the final finished camera actually went on sale.

Comment posted: 27/07/2020

Duncan Gruer on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

I'm also curious what drove the requirements for the legs - I'd have thought that it would be generally used flat.

Comment posted: 27/07/2020

Comment posted: 27/07/2020

Comment posted: 27/07/2020

David Hill on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

Comment posted: 27/07/2020

Matthew King on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

I smiled broadly when I saw all the parts laid out in individual Paterson darkroom trays. Have you considered taking advantage of the fact that the trays are available in more than one colour :)?

I'm wishing you all the best.

Comment posted: 27/07/2020

Emilio F on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

Comment posted: 27/07/2020

Khürt Louis Williams on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 27/07/2020

The challenge with some Kickstarter projects is that someone with a fresh idea, no design experiences, and zero-project management experience using Kickstarter to offload all their risks onto the public. Yes, I know the public is warned of the risks before putting down money. I just wish there was more downside for the project's sponsors when they fail.

Perhaps it's my background in engineering R&D that gives me a perspective most don't have.

Good luck Hamish.

Adrian K Cullen on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 28/07/2020

Michael on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 28/07/2020

I could really imagine the tough hours to find solutions! Really well done! I am really happy to receive my pixl latr soon and to be part of this story! And thx again for your individual advices on my analog shootings ....

Richard Moore on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 30/07/2020

Comment posted: 30/07/2020

Juan on pixl-much-latr – delivering on a Kickstarter 22 months behind schedule

Comment posted: 30/07/2020